Özel Pelet Sobası Motoru

Özellikle pelet sobaları için burgu motorları tasarlama, biyokütle pelet taşımacılığının stabilitesini ve dayanıklılığını artırma konusunda 20 yılı aşkın deneyim.

Pelet sobalarında sıklıkla yakıt tıkanması, anormal motor gürültüsü ve motor sorunları nedeniyle çalıştırılamama gibi sorunlar yaşanır. Yıllar süren ürün optimizasyonu sayesinde bu sorunların yaşanma olasılığını önemli ölçüde azalttık. Ayrıca Avrupa ve Kuzey Amerika'daki pelet fırını üreticileriyle derinlemesine işbirliklerimiz var ve ortaklarımızın önerilerine dayanarak ürün performansını ve üretim süreçlerini sürekli güncelliyoruz.

Fengtech özelleştirir pelet soba motorlari Farklı voltajlar, hızlar, arayüzler, şekiller ve çalışma ortamları için.

Pelet sobası motoru üretim durumları hakkında daha fazla bilgi edinin:

Özel Özelleştirme Vakaları

Normal Çalışma Torku: 20N.m

Yükseltilmiş Versiyon: 25N.m

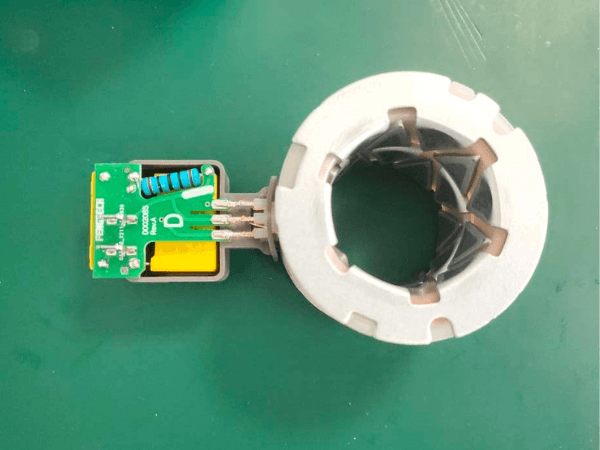

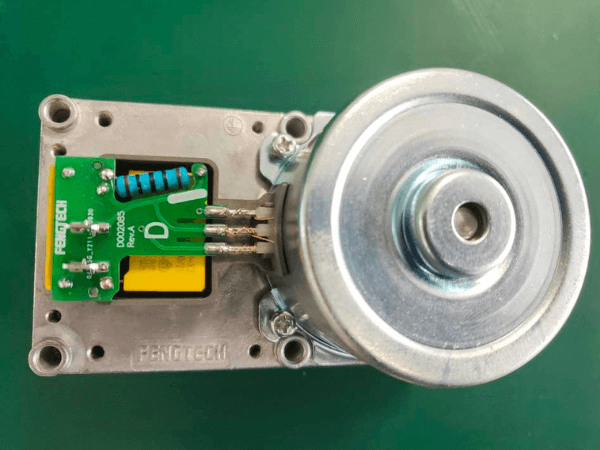

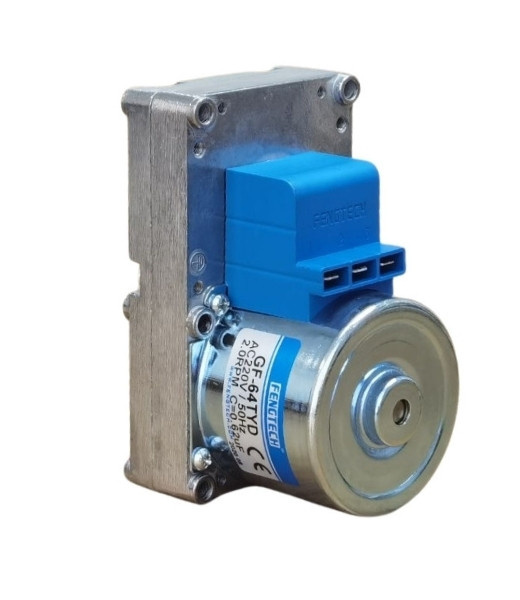

Ek Aksesuarlar: Filtre

(Kullanım ömrünü uzatır, gürültüyü azaltır, güvenilirliği artırır, elektrik şebekesi kirliliğini önler ve diğer ekipmanları etkilemekten kaçınır).

Durma torkunu ve çalışma torkunu artırarak, biyokütle peletleri yanma odasına daha düzgün bir şekilde taşınabilir ve tıkanma olasılığı azaltılabilir.

Filtreli motor, pelet değirmeninin ömrünü uzatır, pelet değirmeninin genel ömrünü artırır, satış sonrası işlemleri azaltır ve kaynak tasarrufu sağlar.

Gürültü seviyesi: 45dB

Dönüş yönü: CW

Nominal kapasitans: 0,75μF

Ortam sıcaklığı: -20 ℃ ila 55 ℃

Filtre

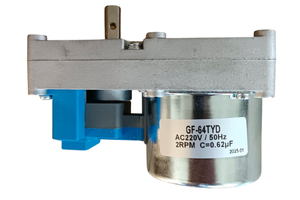

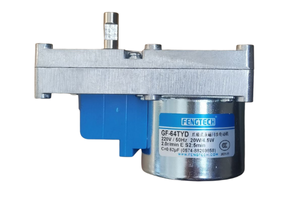

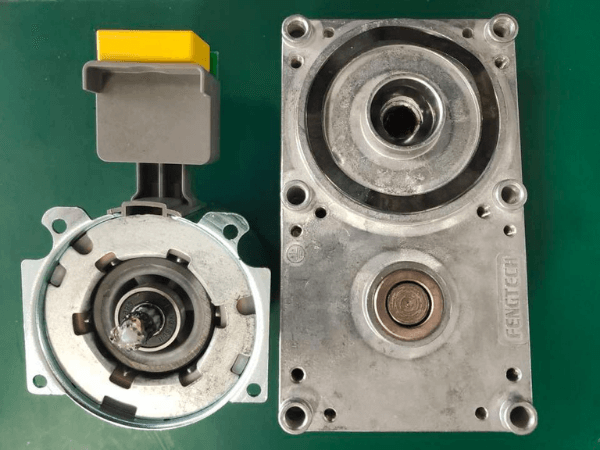

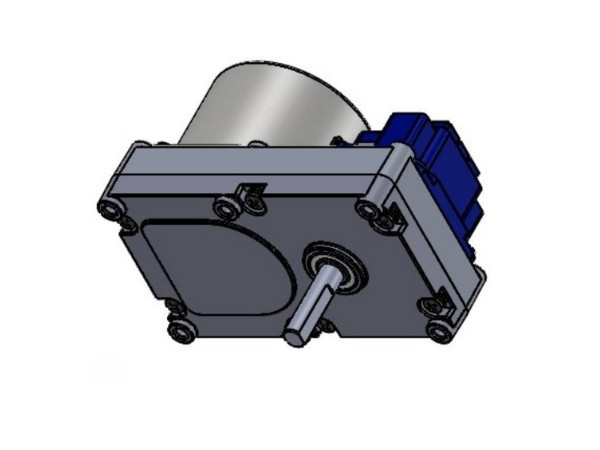

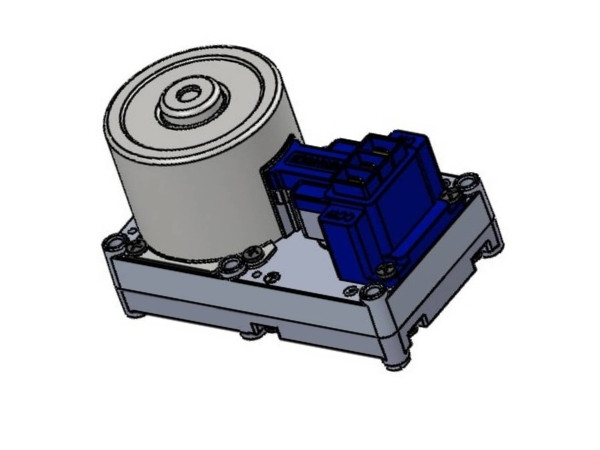

GF-64TYD

Bileşen

GF-64TYD-2

0.58RPM GF-64TYD

Tasarım

Bileşen

GF-64TYD-2

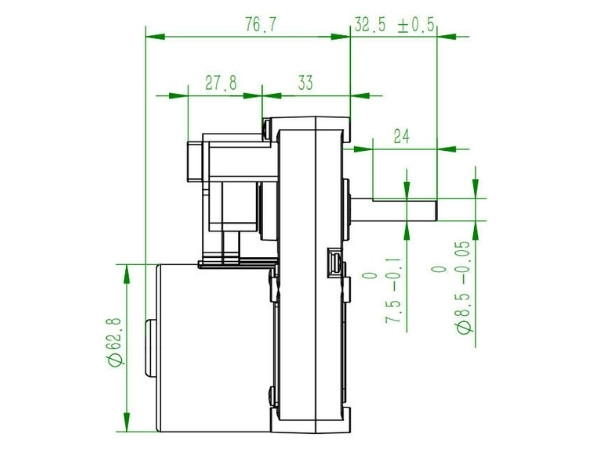

Özelleştirilmiş gereksinimlere dayanarak, yavaşlama verimliliği pelet stiove'daki yaygın 2-3 rpm'den daha da artırıldı ve hız, kullanım ihtiyaçlarını karşılayabilecek 0.58 rpm'ye ayarlandı.

Çıkış mili: 24 mm freze mili

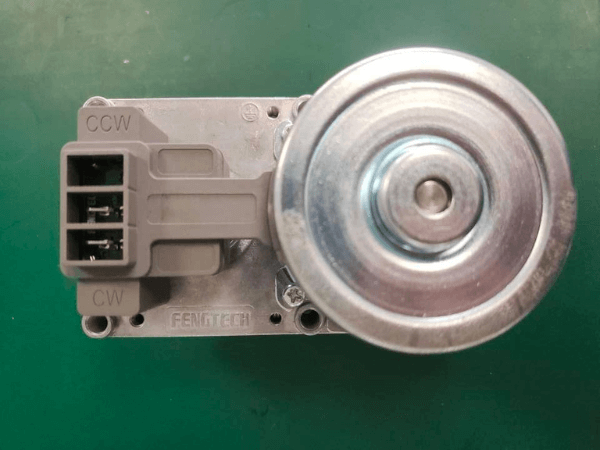

Kablolama Yöntemi: Pim tipi

Voltaj: 220v, 60Hz

Çıkış Hızı: 0.58RPM

Rotasyon: CW/CCW

Durma Torku: 30N.m

Koşu Torku: 20N.m

Farklı Kablolama Yöntemleri

Fengtech, farklı ürün tasarımları için uygun kablolama yöntemleri ve eşleşen güç kabloları sağlar.

pelet soba motorlari i̇çi̇n daha fazla çözüm ve tasarim örneği̇ i̇çi̇n mühendi̇sleri̇mi̇zle hemen i̇leti̇şi̇me geçi̇n.