맞춤형 제빙기 모터

제빙기 공장용 특수 제빙기 모터로 제빙기의 효율성과 안정성을 개선하세요.

제빙기에서 과도한 소음, 토크 부족, 장시간 작동 불능 등의 문제가 자주 발생하나요? 지난 20년간 저희는 제빙기 제조업체, 전기 판매 회사 및 냉동 전문가들과 협력하여 효율적인 얼음 생산에 기여해 왔습니다.

가정용 제빙기든 상업용 제빙기든 Fengtech는 모터와 제어 시스템을 포함한 광범위한 경험과 솔루션을 제공합니다.

가정용 제빙기

가정용 제빙기는 가정, 소규모 파티, 사무실에서 흔히 볼 수 있습니다. 제빙기의 제빙 용량은 다음과 같습니다. 10-30kg. 1년이 지나면 일부 일반 제빙기는 모터 문제로 인해 문제가 발생할 수 있습니다:

- 거칠고 날카로운 소음 방출

- 모터가 작동하지 않습니다.

- 제빙 용량 감소

- 얼음 조각이 끼어 생산할 수 없습니다.

- 흐린 얼음 조각을 생성합니다.

펑테크는 제빙기 모터의 주요 고장을 연구하고 해당 제품을 개발하여 제빙기 수명을 연장했습니다.

모터 FAX-BL70C: DC12/24V 5.5RPM, 최대 토크 30N.m, RS485를 통한 모드버스, 완벽한 보호.

컨트롤 보드: 100~240VAC 입력, 지능형 제어, 전체 보호 시스템.

증발기: 식품 등급 스테인리스 스틸, 고효율 열교환, 15~25kg/일.

리얼 샷

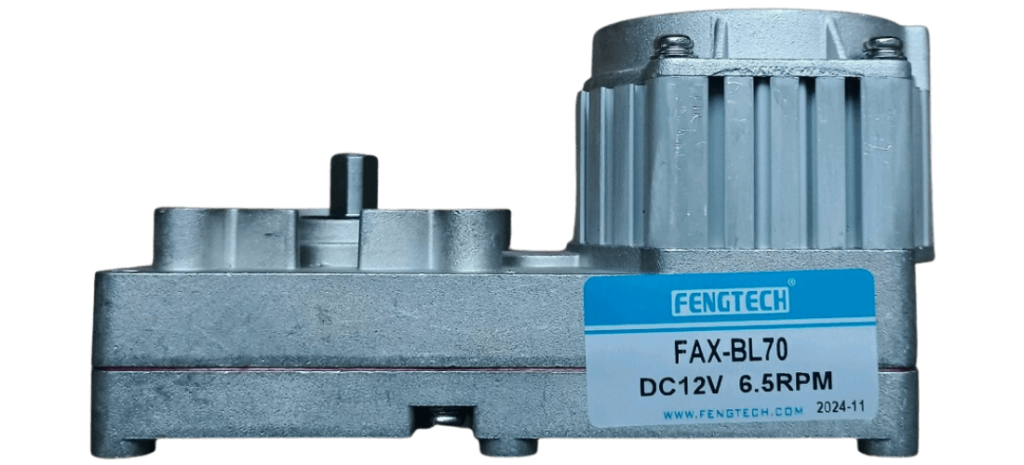

FAX-BL70C

증발기

제어 보드

리얼 샷

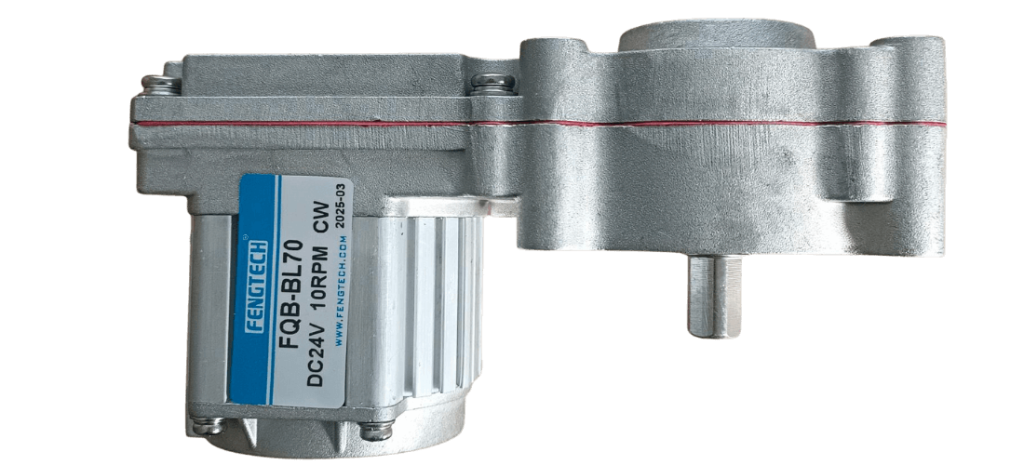

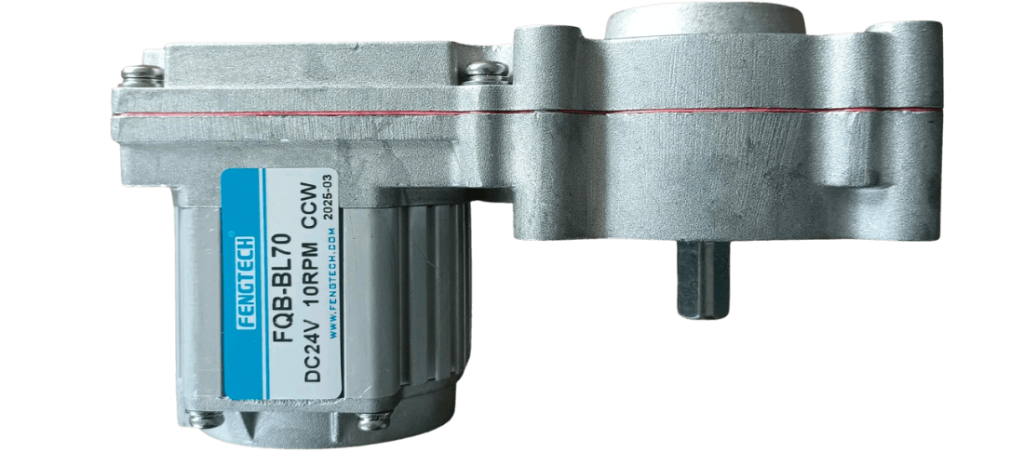

FQB-BL70C

증발기

제어 보드

상업용 제빙기

상업용 제빙기는 일반적으로 중대형 파티, 학교 및 레스토랑 (20 명 이상)에서 사용되며 다음을 생성합니다. 30kg 이상 의 얼음을 매일 만들어야 합니다. 상업용 제빙기는 장시간 작동하기 때문에 오작동이 발생하기 쉽습니다:

- 모터 과열, 열 보호 기능의 빈번한 활성화

- 모터 소음(>50db)

- 얼음 막힘으로 인한 얼음 생산량 감소

- 일관성 없는 얼음 크기

펑테크는 모터, 디스플레이 패널, 제어 시스템, 증발식 냉각기 등 대량의 얼음을 생산하는 제빙기를 위한 종합 솔루션을 제공합니다.

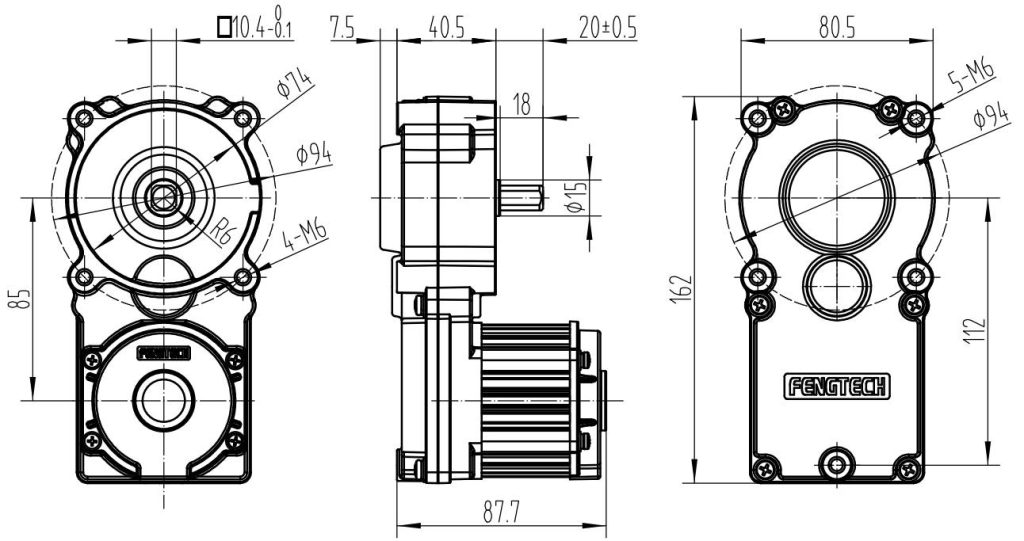

모터 FQB-BL70C: DC24V 10RPM, 최대 토크 35N.m, RS485를 통한 모드버스, 전체 보호 기능

컨트롤 보드: DC24V 입력, 지능형 제어, 전체 보호 시스템

증발기: 식품 등급 스테인리스 스틸, 고효율 열교환, 30~60kg/일

제빙기 모터 제조 사례

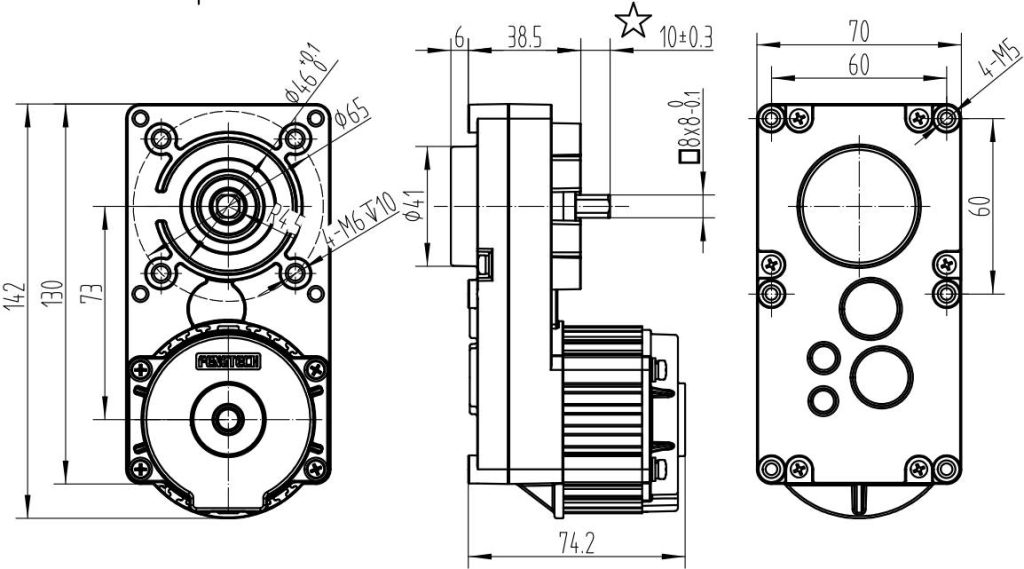

팩스-BL70(DC24V 6.5RPM)

| 1. 정격 특성 | |||

|---|---|---|---|

| 아니요. | 항목 | 사양 | 발언 |

| 1.1 | 작동 전압 | 10~16VDC | 정격 12V |

| 1.2 | 정격 속도 | 6.0 RPM | |

| 1.3 | 정격 토크 | 10 N.m | @ 정격 전압 25℃ 주변 온도 |

| 1.4 | 정격 전류 | 1.2 A | |

| 1.5 | 회전 | 양방향 | |

| 2. 전기적 특성 | |||

| 2.1 | 노로드 전력 | ≤ 6.0 W | |

| 2.2 | 무부하 전류 | ≤ 0.4 A | |

| 2.3 | 노로드 속도 | 6.5 rpm ±10% | @ 정격 전압 25℃ 주변 온도 |

| 2.4 | 최대 토크 | ≥ 30 N.m | |

| 2.5 | 최대 전류 | 3.0 A | |

| 2.6 | 절연 등급 | 클래스 E | |

| 2.7 | 절연 저항. | 100M 옴 민 | |

| 3. 기계적 특성 | |||

| 3.1 | 개요 차원 | 윤곽선 그리기로 | |

| 3.2 | 소음(1m) | 45 Db(A) 최대 | |

| 3.3 | 축 재생 | 최대 0.5mm | |

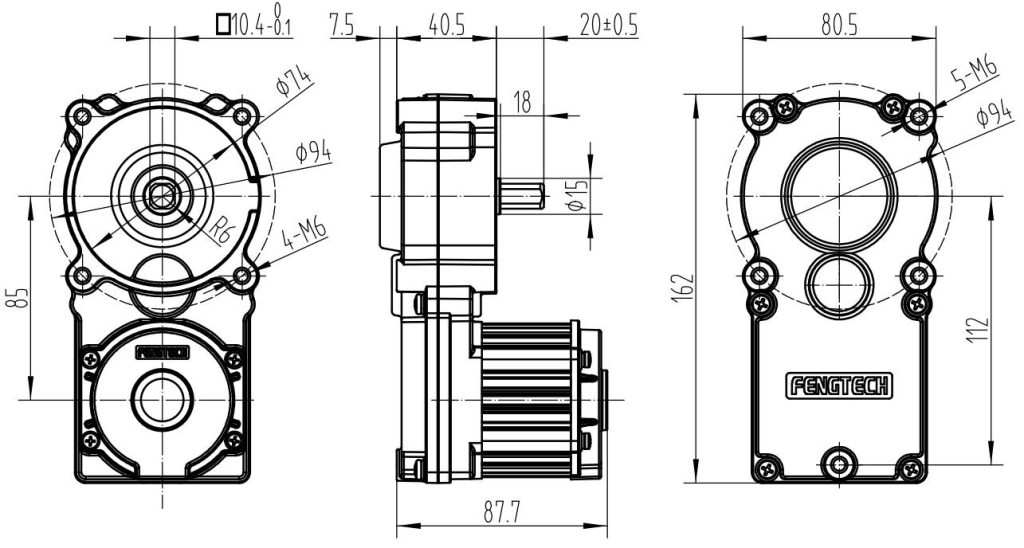

FQB-BL70(DC24V 10RPM CW)

| 1. 정격 특성 | |||

|---|---|---|---|

| 아니요. | 항목 | 사양 | 발언 |

| 1.1 | 작동 전압 | 18~26VDC | 정격 24V |

| 1.2 | 정격 속도 | 10.0 RPM | |

| 1.3 | 정격 토크 | 15 N.m | @ 정격 전압 25℃ 주변 온도 |

| 1.4 | 정격 전류 | 1.0 A | |

| 1.5 | 회전 | CW | |

| 2. 전기적 특성 | |||

| 2.1 | 노로드 전력 | ≤ 9.5 W | |

| 2.2 | 무부하 전류 | ≤ 0.4 A | |

| 2.3 | 노로드 속도 | 10.0 RPM ±10% | @ 정격 전압 25℃ 주변 온도 |

| 2.4 | 최대 토크 | ≥ 30 N.m | |

| 2.5 | 최대 전류 | 2.5 A | |

| 2.6 | 절연 등급 | 클래스 E | |

| 2.7 | 절연 저항. | 100M 옴 민 | |

| 3. 기계적 특성 | |||

| 3.1 | 개요 차원 | 윤곽선 그리기로 | |

| 3.2 | 소음(1m) | 50 Db(A) 최대 | |

| 3.3 | 축 재생 | 최대 0.5mm | |

FQB-BL70(DC24V 10RPM CCW)

| 1. 정격 특성 | |||

|---|---|---|---|

| 아니요. | 항목 | 사양 | 발언 |

| 1.1 | 작동 전압 | 18~26VDC | 정격 24V |

| 1.2 | 정격 속도 | 10.0 RPM | |

| 1.3 | 정격 토크 | 15 N.m | @ 정격 전압 25℃ 주변 온도 |

| 1.4 | 정격 전류 | 1.0 A | |

| 1.5 | 회전 | CCW | |

| 2. 전기적 특성 | |||

| 2.1 | 노로드 전력 | ≤ 9.5 W | |

| 2.2 | 무부하 전류 | ≤ 0.4 A | |

| 2.3 | 노로드 속도 | 10.0 RPM ±10% | @ 정격 전압 25℃ 주변 온도 |

| 2.4 | 최대 토크 | ≥ 30 N.m | |

| 2.5 | 최대 전류 | 2.5 A | |

| 2.6 | 절연 등급 | 클래스 E | |

| 2.7 | 절연 저항. | 100M 옴 민 | |

| 3. 기계적 특성 | |||

| 3.1 | 개요 차원 | 윤곽선 그리기로 | |

| 3.2 | 소음(1m) | 50 Db(A) 최대 | |

| 3.3 | 축 재생 | 최대 0.5mm | |

제빙기 모터 생산 및 조립 공정

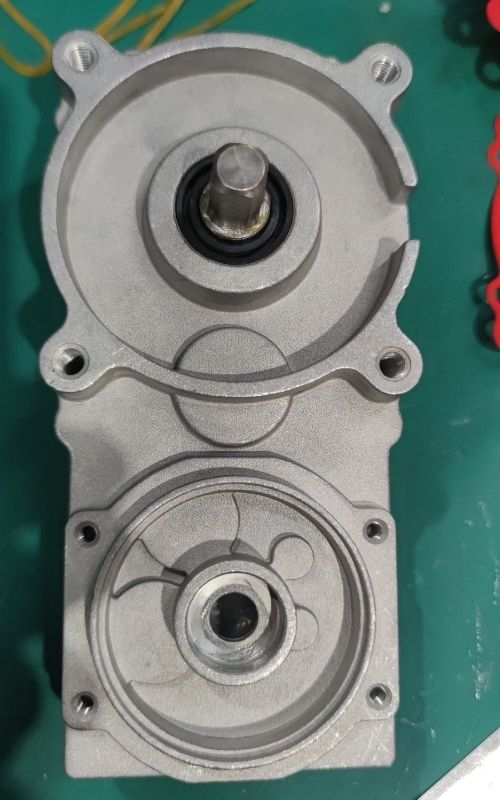

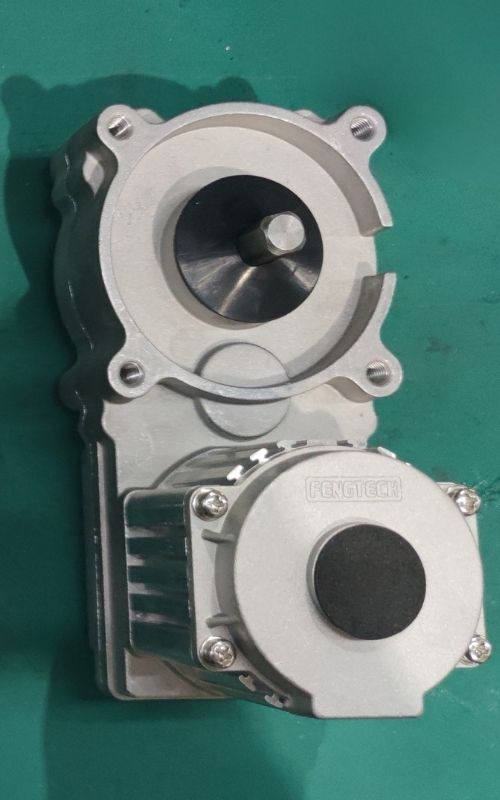

1. 다이캐스트 알루미늄 케이스

제빙기 모터 하우징은 설계 도면에 따라 다이캐스트 알루미늄으로 제작되었습니다. 가볍고 부식에 강하며 경도가 높습니다.

2. 기어 설치

고품질 기어와 베어링을 사용한 정밀 기어 장착 및 출력 샤프트 장착으로 모터 작동의 안정성을 보장합니다.

3. 윤활유 추가

기어에 적절한 양의 윤활유를 추가하면 기어 마모와 소음을 줄일 수 있습니다.

4. 절연 씰링 개스킷 추가

상부 및 하부 커버는 누수, 단락, 단열, 오일 오염을 방지하기 위해 그 사이에 절연 밀봉 개스킷을 끼워 조립됩니다.

5. 방수 링 추가

복잡한 작동 중에 오일과 물이 유입되는 것을 방지하기 위해 출력 샤프트와 모터 방열 영역에 방오 개스킷을 추가합니다.

6. 제빙기 모터 및 냉각기 어셈블리

제빙기 모터와 증발식 냉각기를 모터에 미리 뚫어놓은 구멍을 냉각기에 맞춰 조립합니다.

제빙기 관련 동영상

제빙기 모터 설치 및 제조

가정용 제빙기 모터 테스트

얼음 생산 능력 테스트

전문가와 상담하세요!

프로젝트에 적합한 제빙기 모터 솔루션을 얻으려면 지금 바로 엔지니어 팀에 문의하세요.